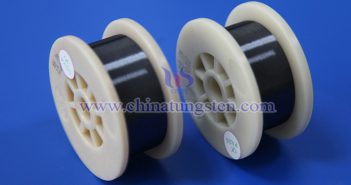

Defrosting glass usually uses tungsten wire as a heating element because tungsten has a high melting point, high temperature resistance and good conductivity, which is suitable for generating uniform heat on the glass surface or in the interlayer to remove frost or ice. 1. Working Principle of Tungsten Wire in Defrosting Glass Tungsten wire is embedded or attached to the interlayer or surface of glass (such as the rear windshield of a car or the glass door of a refrigerator).…