Tungsten-nickel-iron alloy is a material with tungsten as the matrix (typically 90%–98% tungsten content), formed by adding nickel, iron, and other elements. Its physical properties stem from the synergistic effect of tungsten’s high hardness and the toughness of the nickel-iron binder phase, which can be optimized by adjusting composition ratios and preparation processes.

I. High Strength and Tensile Performance

The alloy’s tensile strength ranges from 700 to 1,000 MPa, primarily due to the rigid tungsten particle framework, with tungsten’s Mohs hardness reaching 7.5. The nickel-iron binder phase envelops the tungsten particles, forming a continuous matrix that effectively transmits stress under external forces. For instance, in aerospace, it is used to manufacture gyroscope rotors, where high strength ensures structural stability during high-speed rotation, preventing deformation or fracture from centrifugal forces.

II. Good Ductility

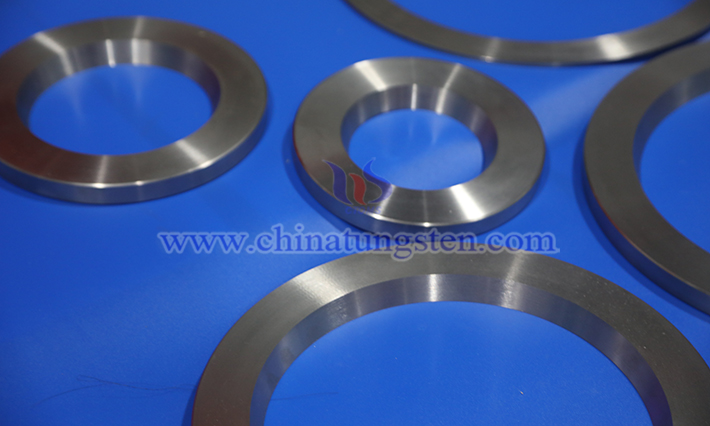

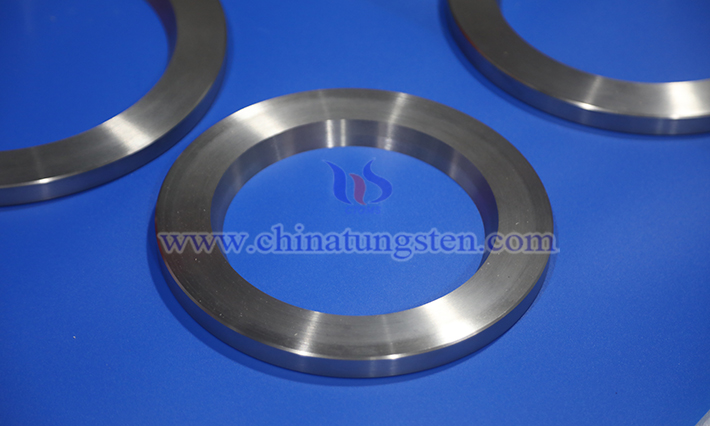

Unlike pure tungsten, which is highly brittle and difficult to process, the introduction of a nickel-iron binder phase enhances the alloy’s plasticity. This advantage allows it to be shaped into complex parts via forging or rolling, such as die-casting molds in mechanical manufacturing. During die-casting, molds endure repeated high-temperature and high-pressure impacts, and the alloy’s ductility helps absorb energy, avoiding brittle fracture and extending mold lifespan.

III. High Hardness and Wear Resistance

The alloy’s high hardness arises from the rigid tungsten particles and the solid-solution strengthening effect of the nickel-iron phase. In military equipment manufacturing, it serves as an armor-piercing projectile core, where high hardness maintains structural integrity during high-speed impacts with armor, minimizing kinetic energy loss from deformation.

IV. Controllable Thermal Expansion Coefficient

The thermal expansion coefficient of tungsten-nickel-iron alloy is typically 1/2 to 1/3 that of iron or steel (depending on composition). This property offers unique advantages in applications requiring thermal matching. For example, in manufacturing watch counterweights, the alloy’s low thermal expansion coefficient prevents changes in fit gaps due to temperature fluctuations, ensuring accurate timekeeping. Additionally, in high-temperature environments, the low thermal expansion reduces structural deformation from thermal stress, enhancing equipment reliability.

V. Radiation Absorption and Shielding Performance

Tungsten-nickel-iron alloy exhibits strong absorption capabilities for ionizing radiation such as γ-rays and X-rays, attributed to tungsten’s high atomic number and density. For instance, in nuclear power plants, shields made from this alloy effectively block radiation from reactors, ensuring worker safety.