Defrosting glass usually uses tungsten wire as a heating element because tungsten has a high melting point, high temperature resistance and good conductivity, which is suitable for generating uniform heat on the glass surface or in the interlayer to remove frost or ice.

1. Working Principle of Tungsten Wire in Defrosting Glass

Tungsten wire is embedded or attached to the interlayer or surface of glass (such as the rear windshield of a car or the glass door of a refrigerator). By heating with electricity, heat is generated to increase the temperature of the glass surface, thereby melting frost or ice and preventing fog from condensing.

2. Advantages of Tungsten Wire for Defrosting Glass

High melting point: The melting point of tungsten is about 3422°C, which can withstand high temperatures without being easily damaged.

Conductivity: Tungsten wire has moderate resistance and can efficiently convert electrical energy into thermal energy.

Durability: Corrosion-resistant, suitable for long-term use.

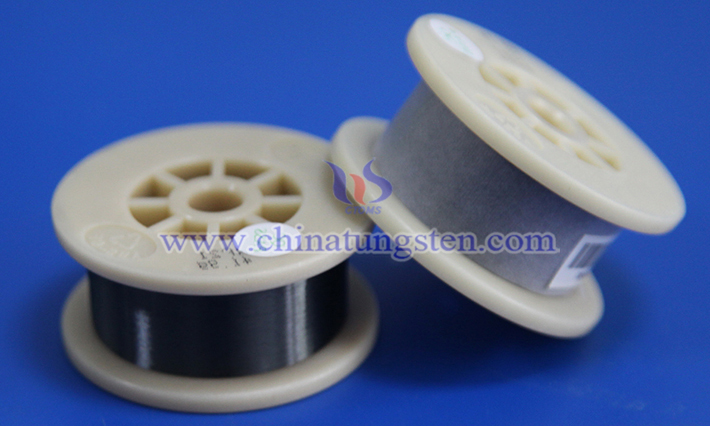

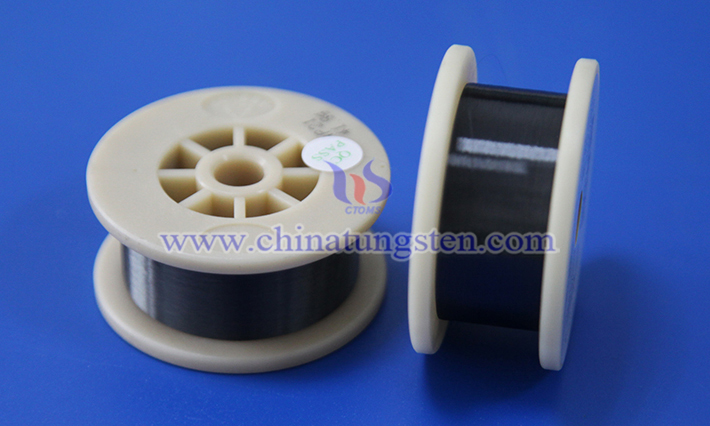

Small and flexible: Tungsten wire can be made into very fine lines and embedded in glass without affecting transparency or aesthetics.

3. Application of Tungsten Wire for Defrosting Glass

Embedded in the interlayer: The extremely fine tungsten wire is embedded in the laminated glass in the form of a grid or parallel lines, fixed by a special gluing process to ensure uniform heating and not affect the transparency of the glass. It is often used in the rear windshield of the car.

Surface attachment: Tungsten wire is directly adhered or pressed on the surface/back of the glass in the form of fine wires, connected to the power supply to form a heating circuit, suitable for refrigerator or freezer glass doors.

Micro-machining: Tungsten wire is arranged into a specific pattern (such as wavy or straight lines) through precision technology and fixed on the inner layer or surface of the glass to ensure uniform heat distribution and minimal visual interference.

4. Precautions for the Application of Tungsten Wire in Defrosting Glass

Uniformity: Tungsten wire needs to be evenly distributed to ensure that there is no dead angle for heating.

Energy consumption: The circuit design needs to be optimized to reduce energy consumption.

Safety: Ensure that the tungsten wire is tightly bonded to the glass to avoid short circuit or overheating.