Insulated gate bipolar transistor (IGBT) is a semiconductor device widely used in power electronic systems, which plays an important role in industrial automation, new energy vehicles, rail transit, and smart grid due to its high efficiency, fast switching characteristics, and high withstand voltage capability. However, IGBTs generate a lot of heat during operation, so efficient heat dissipation and stable mechanical structure are essential for their reliability.

Molybdenum-copper (Mo-Cu) alloys play a vital role in IGBT packaging. Its high thermal conductivity, good thermal expansion matching, and excellent mechanical properties make it an ideal material for IGBT substrates, heat sinks, and lead frames.

The packaging of the IGBT module needs to meet the following key requirements:

1. High thermal conductivity: The heat generated by the IGBT chip during operation needs to be quickly conducted to the heat sink to prevent overheating from degrading performance or failure.

2. Low coefficient of thermal expansion matching: IGBT chips are usually made of silicon (Si) or silicon carbide (SiC), which have a low coefficient of thermal expansion (Si about 2.6 × 10??/K). The CTE of the packaging material needs to be matched to the chip to reduce interfacial stress and cracks caused by thermal expansion mismatch during thermal cycling.

3. High strength and reliability: The encapsulation material needs to have sufficient mechanical strength to withstand external mechanical stress and thermal cycling fatigue to ensure long-term stability.

4. Good electrical properties: The material should have good electrical conductivity to reduce parasitic resistance and improve the electrical properties of IGBT modules.

In IGBT packaging, molybdenum-copper alloy is mainly used for the following key components:

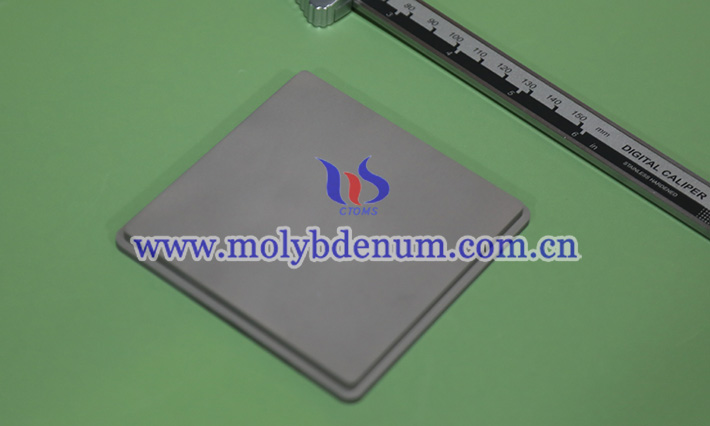

1.Substrate

The substrate of the IGBT module usually uses the Mo-Cu alloy as the transition layer to connect the chip and the heat sink. The Mo-Cu substrate can effectively reduce the interfacial thermal stress and improve the thermal stability of the module.

2.Heat Spreader

Since IGBT modules generate a lot of heat at high power, Mo-Cu alloy as a heat sink material can efficiently conduct heat from the chip to the external heat sink. Its excellent thermal conductivity and CTE matching make it excellent in packages with high-power IGBT templates.

3.Lead Frame

Mo-Cu alloys can be used in the lead frame of IGBT template packages to provide stable mechanical support and good electrical conductivity. Its low thermal resistance helps to reduce parasitic resistance inside the package and improve device efficiency.