Tungsten oxide nanorod may be prepared through a hydrothermal process at 180°C by using sodium sulfate (Na2SO4) as a directing reagent, and may be applied in the photocatalytic degradation of RB under visible light irradiation.

Synthesis of Tungsten Trioxide Nanorod

1. Dissolve 2.77g sodium tungstate and 4.77g Na2SO4 in 67.5ml water and stir completely.

2. Adjust the pH to 1.5 with 3mol/L hydrochloric acid (HCL) and stir for 30min.

3. Heat the above solution at 180°C for 48 h.

4. Wash the obtained product 3 times with water and 3 times with alcohol respectively, dried at 65°C.

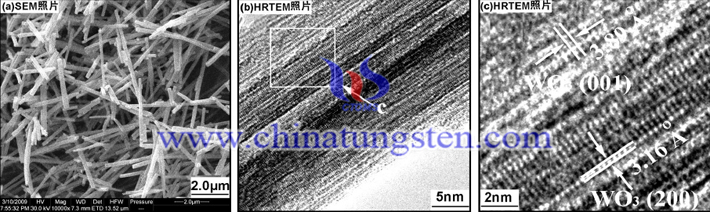

The obtained nanorod has a diameter of 20~40nm and a length of 1~5μm. And it has large aspect ratio and uniform thickness. Also, WO3 nanorod prepared by hydrothermal method exhibits higher photocatalytic activity than the WO3 synthesized by precipitation method as the former has high specific surface and fast carrier transmission rate.

Formation Mechanism of Tungsten Trioxide Nanorod

During the growth of WO3 nanorod, Na+ preferentially adsorbed on the WO3 (200) crystal surface, which inhibited the further growth of the crystal face, thereby allowing the nanorod to grow toward along the preferred (001) crystal face. The nanorod exhibits better photocatalytic properties under visible light.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide-nanorod.html