The diameter of tungsten wire plays a significant role in determining the cut-resistance properties of the knitted fabric. Here's how it affects the fabric:

Increased Diameter, Higher Cut Resistance:

Thicker W Wire: A larger diameter W wire increases the fabric's resistance to cutting forces. This is because thicker wires are more difficult to sever, providing a stronger barrier against sharp objects. The greater mass and cross-sectional area of thicker wires can better absorb and distribute the force applied by a cutting edge, enhancing the overall protection.

Decreased Diameter, Flexibility, and Comfort:

Thinner W Wire: While thinner W wires are less resistant to cutting forces compared to thicker ones, they contribute to the fabric’s flexibility and comfort. Finer wires allow for a tighter weave or knit, creating a dense fabric that still offers good protection while being more comfortable to wear. Thinner wires also reduce the overall weight of the fabric, which is important in applications where mobility and comfort are critical.

Optimal Balance:

Optimal Balance:

Balancing Diameter and Fabric Properties: The ideal W wire diameter in cut-resistant fabrics often requires a balance between maximizing cut resistance and maintaining flexibility, comfort, and lightweight characteristics. If the wire is too thick, the fabric may become stiff, heavy, and less wearable. If it's too thin, the cut-resistant properties might be compromised. Manufacturers often choose a wire diameter that offers sufficient protection while ensuring the fabric remains practical for its intended use.

Weaving/Knit Pattern:

Integration with Fabric Structure: The effect of W wire diameter also depends on how the wire is integrated into the fabric. For instance, a thicker wire in a looser weave might offer similar or better cut resistance compared to a thinner wire in a tighter weave, depending on the application. The knitting or weaving pattern, along with the wire diameter, collectively determines the final cut-resistance level.

The diameter of tungsten wire directly impacts the cut-resistance, flexibility, weight, and comfort of the knitted fabric. The choice of diameter should align with the specific requirements of the application, balancing protection with practicality.

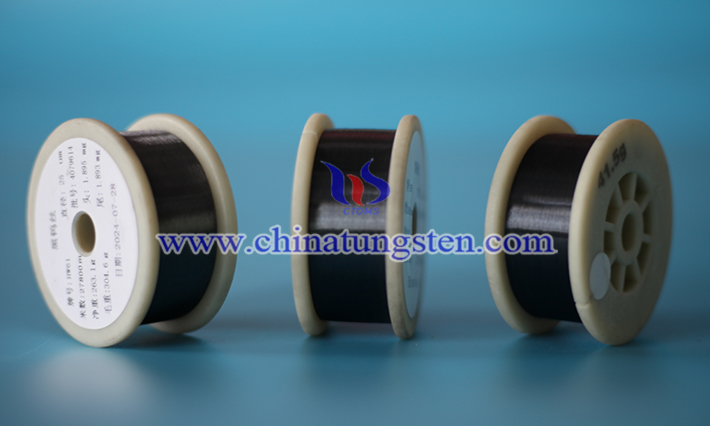

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum for nearly thirty years, and can provide tungsten wires for various applications. Please free feel to contact us when you got the purchasing plans.