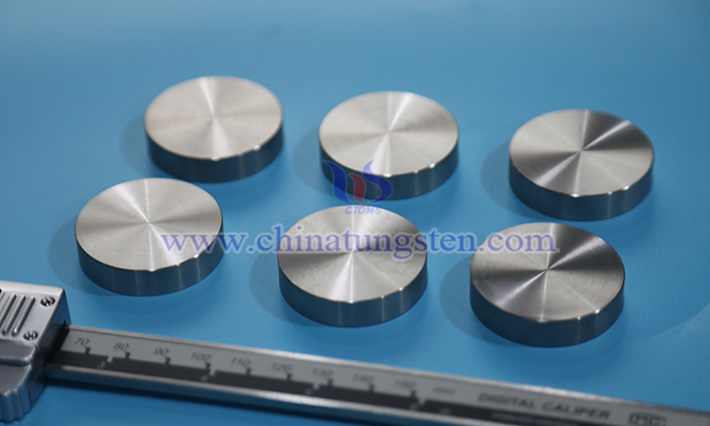

Tungsten-nickel-iron alloy boasts high density, high tensile strength, excellent radiation absorption, and good processability, making it widely applicable in aerospace counterweights, armor-piercing projectile cores, nuclear radiation shielding, and medical equipment protection. Beyond tungsten content, powder characteristics, production processes, and process parameters, the nickel-iron ratio is another key factor influencing its performance.

The nickel-iron ratio significantly affects the alloy’s properties by regulating its phase composition and microstructure, thereby altering its mechanical, physical, and processing characteristics.

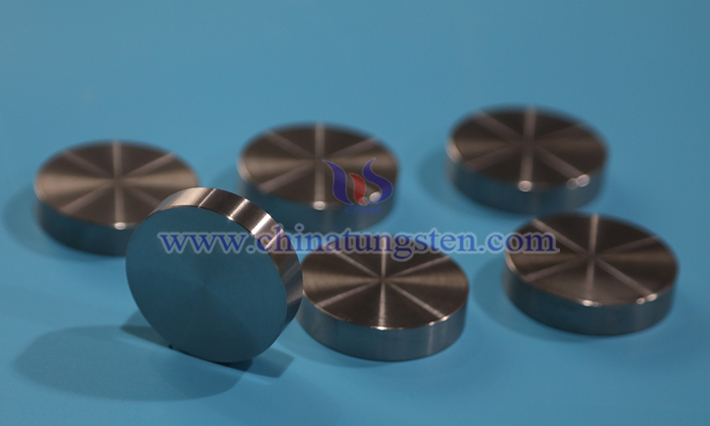

Mechanical Properties: The nickel-iron ratio impacts the balance between strength and toughness. Under traditional processes, a 7:3 nickel-iron ratio yields a uniform binder phase, offering high tensile strength (900–1,000 MPa) and elongation (18%–29%). Increasing the ratio to a certain level with solution quenching can enhance both strength and toughness simultaneously; however, exceeding a critical ratio may lead to the precipitation of brittle intermetallic compounds, degrading performance.

Physical Properties: The nickel-iron ratio influences the binder phase’s electrical conductivity, thermal conductivity, and thermal expansion, shaping the alloy’s overall properties. Generally, higher nickel content improves conductivity, broadening its use in welding and lighting applications.

Processing Properties: The nickel-iron ratio affects the alloy’s plastic deformation capacity. Alloys with traditional ratios (7:3 or 1:1) exhibit good weldability and machinability, suitable for complex-shaped parts. However, high nickel-iron ratio alloys may form brittle phases during slow cooling post-sintering, worsening processability. Solution quenching and other heat treatments can suppress phase transformations, restoring ductility.